Introduction

Mini crawler cranes earn their reputation in places larger machines can’t reach: rooftops, mezzanines, production halls, courtyards, and narrow alleyways. These settings impose strict limits on footprint, noise, emissions, and ground bearing. They also punish delays—permits expire, neighbors complain, and production lines wait for one critical lift. When the plan puts stability first and the equipment is specified for real constraints, compact crawlers turn hard jobs into repeatable operations.

The focus below is practical: the pain points that slow projects and the concrete benefits a well-chosen mini crawler brings to site teams, owners, and facility managers.

1. The problems that derail “small-space” lifting

1.1 Access that looks impossible

Door widths, corridor corners, stairwell turns, low gates, and rooftop parapets stop conventional cranes at ground level. Even if a larger crane can reach, street closures, escorts, and counterweight trucks multiply cost and risk.

1.2 Fragile or unknown support underfoot

Roofs, mezzanines, and tiled factory floors dislike concentrated loads. Many failures begin not with the crane, but with a leg set on a weak span, a trench cap, or a membrane that wasn’t protected.

1.3 Safety margins disappear fast in tight spaces

A gust on a panel, a slewing tail too close to a parapet, or a small off-level angle can erase stability headroom. With pedestrians or production staff nearby, the tolerance for error is near zero.

1.4 Productivity leaks everywhere

If every pick demands extra spotters, repeated re-rigging, and constant repositioning, a one-day scope stretches into two. Hidden costs—permits, lane control, overtime—pile up.

1.5 Compliance pressure in cities and plants.

Noise and emission limits make diesel-only cranes awkward. Fume extraction indoors, nighttime restrictions, and sensitive neighbors turn logistics into a second full-time job.

2. How mini crawler cranes address those pains—feature by feature, benefit by benefit

2.1 Slim chassis with tracked mobility → Access secured without demolition.

Mini crawlers travel through standard doorways, pivot tightly down corridors, and climb gentle ramps. Tracks spread travel loads to protect finished surfaces, while the compact superstructure keeps tail swing controlled.

Benefit: crews reach the work face without building modifications or long detours.

2.2 Outrigging “spider” legs → Big stability from a small footprint.

Fold-out outriggers create a wide stability polygon relative to machine size. With properly sized pads or mats, outrigger reactions spread across beams or reinforced zones, keeping local bearing pressures within limits.

Benefit: you lift confidently where a conventional truck chassis would overload the surface.

2.3 Electric and hybrid power options → Compliance without drama.

Battery-electric or tethered electric packs remove exhaust and hush the job.

Benefit: simplified permits indoors and at night, happier neighbors, and safer conditions for crews working alongside production.

2.4 Proportional control with modern load monitoring → Smooth, predictable placement.

Handset displays that show angle, outreach, and utilization help operators make micro-corrections before hitting a limit.

Benefit: fewer scuffs, fewer “back-and-forth” hand signals, and shorter cycles near delicate façades, glass, or pipework.

2.5 Attachment readiness → One machine, many tasks.

Glass lifters, small jibs, baskets, and spreader bars install quickly.

Benefit: a single mobilization covers varied lifts, cutting rigging time and crew requirements.

2.6 Pick-and-carry envelopes (where permitted) → Fewer resets.

Some models allow short, slow creeps with a suspended load within a narrow radius window.

Benefit: position the final pick without redeploying outrigger pads at every meter.

3. Rooftops: finishing lifts without owning the street below

- Pain: roof membranes tear, parapets constrain swing, and gusts strike hardest at height.

- What solves it: composite mats to protect the membrane, spreader timbers that bridge to structural beams, and conservative wind caps baked into the method statement. Mini crawlers shine because the outrigger footprint can be tuned to the roof’s strong points, and the total machine weight stays low enough for typical decks.

- Outcome in practice: HVAC swaps and signage placements complete within a single work window—no lane closures, no extended barricades, and no diesel fumes drifting into offices. The saved time isn’t only at the hook: mobilization is simpler, permits are easier, and the building manager signs off faster.

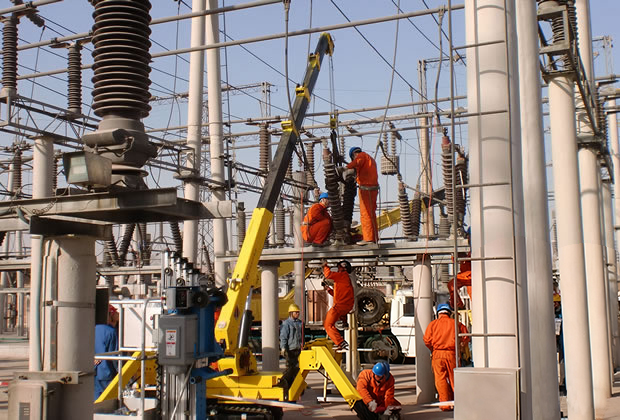

4. Factories and plants: precision lifts inside real constraints

- Pain: tight aisles, sensitive equipment, and zero tolerance for fumes.

- What solves it: battery-electric minis with fine proportional control. Outriggers deploy within marked floor boxes, and mats spread reactions across known strong points. Teams coordinate with—or separate from—overhead cranes through lockout procedures.

- Outcome in practice: MEP modules, gearboxes, motors, and process skids land exactly where they belong, often in one shift instead of two. There’s no scramble for ventilation or after-hours premiums, and production managers see less interruption.

5. Narrow urban job sites: footprint discipline that saves hours

- Pain: curb lanes, alleyways, courtyards—every meter matters.

- What solves it: vertical or dual-stage outriggers that stay within lane lines; fast, repeatable deployment; and remote operation that lets the operator stand at the load. Electric power respects quiet hours and reduces the paperwork burden.

- Outcome in practice: crews meet tight municipal windows, traffic control budgets shrink, and neighbors experience less disruption. Shorter setups translate into more picks per day.

6. Stability as a system: base, geometry, environment

A stable lift is not a guess; it’s engineered.

6.1 Base (what you stand on)

Calculate pad area from expected leg loads and allowable bearing pressure. If data is uncertain, assume less capacity and enlarge pads. Avoid voids, conduits, and unbraced deck sections; bridge to beams when necessary.

6.2 Geometry (how you configure the crane)

Plan by radius, not just load weight. Use the chart page that matches outrigger spread and slew zone. If you add a jib or manual extension, switch to the appropriate tables. Where pick-and-carry is used, follow the tiny envelope exactly—stationary capacity does not apply.

6.3 Environment (the day you actually get).

Rooftop gusts and small slopes erase headroom fast. Build 10–20% capacity margin after rigging and expected derates. Tag-lines on sail-area loads are not optional; they are how you keep the hook calm.

Business outcome: fewer lockouts, fewer scares, and fewer resets. The method statement becomes predictable, so schedulers and stakeholders trust your plan.

7. Reading capacity like a planner (not like a brochure)

- Determine the net mass at the hook (load + slings + spreader + lifting tool).

- Measure the real radius from slewing center to hook path. Round up if in doubt.

- Choose the exact chart page: full/mid/retracted spread, over-side vs. over-front, jib/no jib.

- Check the limiting mode on the cell—stability-limited calls for extra care on ground and wind; structural-limited demands attention to reeving, rope layers, and boom angle.

Check the nacelle’s limiting mode—stability-limited mode requires extra caution with ground and wind forces; structure-limited mode requires attention to line threading, line routing, and jib angle.

8. Spec decisions that move the ROI needle

8.1 Power system

Battery-electric or tethered electric turns difficult permits into routine jobs and opens quiet-hour windows. For mixed indoor/outdoor work, a low-emission engine with auto-idle may suffice. Choose what your calendar actually needs.

8.2 Outreach where you live

The most important number often isn’t the short-radius headline capacity; it’s what the crane can lift at 8–12 m outreach in the zones you use most. Buy for that number.

8.3 Outrigger architecture

Models with vertical or dual-stage legs work inside lane lines and narrow aisles. If your jobs demand frequent micro-moves, this design pays back quickly.

8.4 Controls and feedback.

A handset that shows angle, outreach, and utilization shrinks radio chatter and reduces accidental over-commit. Operators perform better when they can “see” the numbers, not guess them.

8.5 Protection and sealing.

Ingress protection, hose sleeving, and tidy cable management are not luxuries on rooftops or factory floors. The day you avoid a nuisance downtime is the day these choices pay.

9. A short ROI lens (so benefits translate into numbers)

- Cycle time: If proportional control and close-in operation save 5–8 minutes per pick and your team makes 12 picks per day, you just recovered one to two hours—often enough to add an extra lift or finish early with the same crew.

- Traffic control: Each avoided lane closure or permit amendment is direct margin. Mini crawlers often operate inside curb lines and below complaint thresholds.

- Damage avoidance: One avoided façade scratch, bent duct, or cracked tile can equal a month of finance payments. Careful placement and lower ground pressure matter.

- Permit friction: Electric drives reduce back-and-forth with authorities and building management. Less negotiation is more time on the hook.

10. Case snapshots (adaptable to your method statements)

10.1 Rooftop HVAC replacement

A mid-class mini crawler was flown at dawn, tracked on mats to a planned position, and bridged two legs across a weak deck zone with timber spreaders. With a 580 kg unit at 9.5 m outreach and 110 kg of rigging, the crew kept a 15% margin and set a 7 m/s wind limit. Three swaps finished in one morning; no lane closures and no tenant complaints.

10.2 Factory gearbox install

A compact electric unit threaded between columns to land a 410 kg gearbox on a mezzanine at 8.2 m outreach. No fumes, no ventilation rig-up, and zero interruption to adjacent lines. The changeover compressed from two shifts to one.

10.3 Alley glazing

Dual-stage outriggers stayed within the curb line while a glass lifter placed 230 kg panes over a 4 m parapet. The operator watched utilization on the remote, easing in without façade contact. The crew completed the elevation before stores opened.

11. Implementation checklist (copy, customize, repeat)

- Confirm allowable bearing pressure and calculate pad areas from expected leg loads.

- Map the access path with real dimensions—door widths, elevator car size, tight turns, ramp grades.

- Fix wind and slope thresholds in the method statement; establish a tag-line plan for sail-area loads.

- Program tool presets in the controller and verify loss-of-link behavior on the remote.

- Conduct a dry-lift to 100–150 mm and compare LMI utilization with plan before committing.

- Log radius, pads used, wind readings, and any alerts so the next lift gets easier.

12. What owners care about after delivery

12.1 Service rhythm that protects stability.

Re-torque structural fasteners at 50–100 hours, inspect filters, verify pressures/flows quarterly, and schedule annual structural checks where regulations apply. A crane that “drifts” or chatters is asking for maintenance, not more throttle.

12.2 Spares that matter.

Remote batteries, an antenna, outrigger pads, and common seal kits cost little and save days.

12.3 Training that sticks.

Walk crews through reading charts, measuring radius, leveling, and the exact loss-of-link response. When everyone uses the same vocabulary (radius, spread, limiting mode), near-misses fall.

Conclusion

Mini crawler cranes are not merely smaller cranes—they are stability solutions engineered for roofs, factories, and tight city sites. They cure the access problem with narrow tracked mobility; they cure the ground problem by spreading reactions; they cure the compliance problem with quiet electric power; and they cure the productivity problem with proportional control and attachment versatility. The outcome is simple and valuable: fewer disruptions, faster cycles, cleaner audits, and safer crews.

If your calendar is full of constrained lifts, choose a mini crawler matched to the outreach you actually use, the surfaces you stand on, and the rules you operate under. Size pads from real leg loads, level the machine, set a wind cap you’ll enforce, and let the controller’s limits work for you. Do that consistently, and the “impossible lift” becomes just another line on tomorrow’s schedule—finished on time, without drama.