Introduction

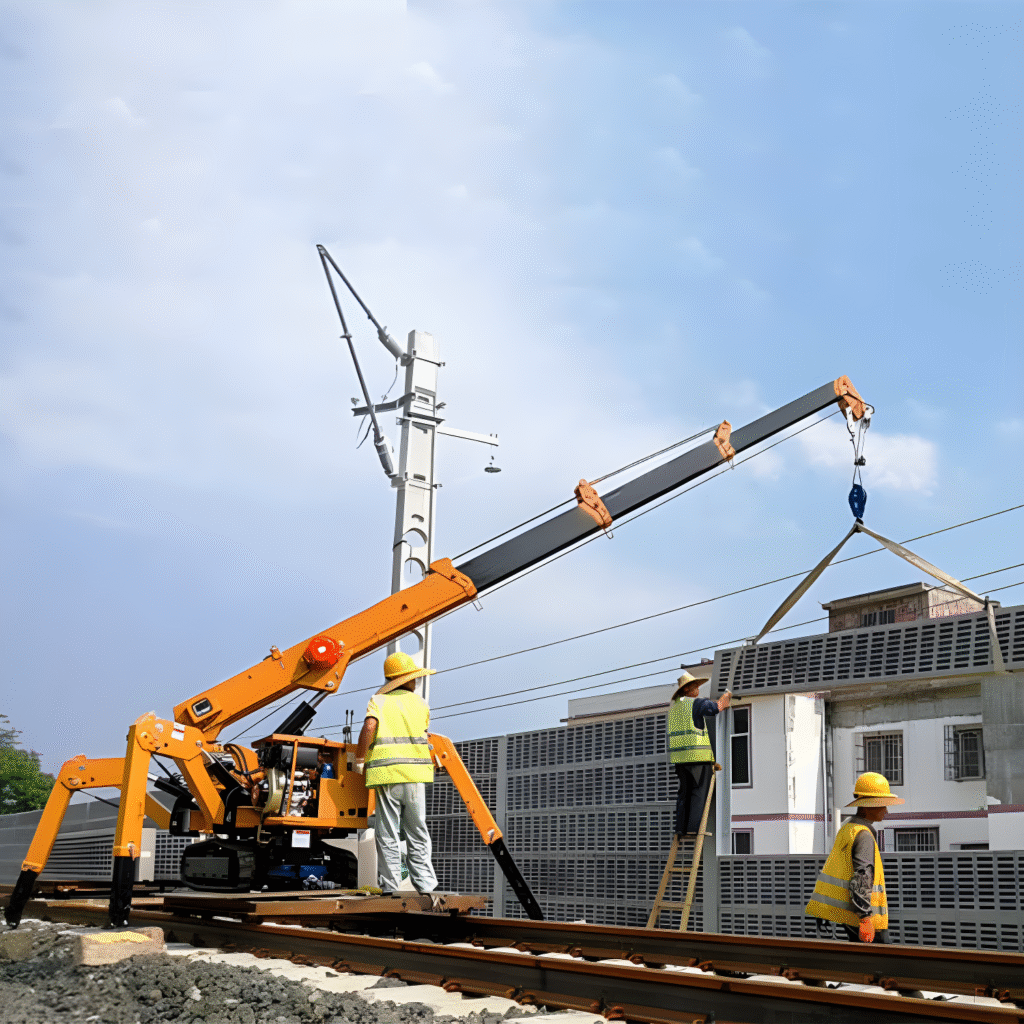

A tracked spider crane gets its name from the crawler base and retractable outriggers that allow it to work in a wide range of challenging conditions. It is mainly used where standard lifting equipment struggles to operate safely or efficiently.

The crane is built around a tracked chassis—rubber or steel depending on application—and a high-strength boom designed for compact lifting work. This configuration allows it to move over uneven ground such as soft soil, snow-covered surfaces, or narrow access areas, while maintaining stable positioning during lifting. Control systems are designed to manage lifting, slewing, telescoping, and steering within limited space rather than for high-speed operation.

Tracked spider cranes are typically offered in capacities from about 1.2 to 16 tons, covering everything from small indoor lifts to heavier outdoor work. They are frequently used on power construction sites, municipal projects, and emergency operations where space is limited and precise positioning is required.

1. Core Technology and Product Advantages

In real operating conditions, the performance of a tracked spider crane is shaped more by its structural design than by headline specifications. How the machine handles limited access, uneven ground, and setup constraints is often what determines whether it can be used effectively on site.

Mobility and Chassis Design

Movement is handled by a hydraulically driven crawler chassis. Rubber tracks are usually chosen for indoor work or finished surfaces where ground protection is required, while steel tracks are applied on rough or uneven terrain. With relatively low ground pressure, the crane can travel steadily on slopes of around 25°, maintaining traction in situations where wheeled equipment often struggles.

Outriggers and Ground Adaptability

Stability comes from a three-stage telescopic outrigger system. The outriggers are manually extended and supported by hydraulics, with a maximum spread of approximately 7,860 mm. This arrangement allows the crane to remain stable on irregular ground conditions, which are frequently encountered in renovation projects and infrastructure work.

Boom Structure and Lifting Range

The boom is built from high-strength manganese steel and configured according to lifting capacity. Smaller models, such as the 1.2-ton version, offer boom lengths of about 6.3 meters, while larger models up to 16 tons can extend to roughly 25 meters. The number of boom sections can be adjusted to match different working radii and site layouts rather than relying on a single fixed configuration.

Control and Monitoring

Depending on the model and setup, operation can be performed either manually or via wireless remote control. Some versions include torque monitoring, which provides real-time feedback on lifting load and helps operators stay within safe operating limits during lifting tasks.

Power Options and Environmental Adaptability

Available power configurations include gasoline, diesel, and dual-power systems. Electric starting is standard, and the equipment is designed to operate reliably in temperatures ranging from approximately –50 °C to 45 °C. For models above 3 tons, diesel engines are most common, with certain versions allowing switching between electric and diesel power to balance noise, emissions, and fuel consumption.

Compact Dimensions and Deployment

A key characteristic of spider cranes is their compact footprint. Minimum body width can be as narrow as 0.65 meters, allowing access through doorways, corridors, and other confined spaces. In practical use, a single operator can typically complete outrigger deployment and boom setup within about 5 to 10 minutes, which is noticeably faster than the setup process for traditional cranes.

Model Range and Configuration

Tracked spider cranes are generally available in rated capacities of 1.2, 1.5, 2, 3, 4, 5, 8, 10, 12, and 16 tons. This range supports both indoor lifting tasks and larger outdoor engineering work. As capacity increases, working radius and lifting height increase accordingly, while track widths—ranging from roughly 180 mm to 400 mm—are selected to suit different ground conditions.

Optional features may include torque limiters, lifting baskets, hydraulic boom extensions, wireless remote controls, and various color finishes. These options allow the crane to be configured for specific operational needs rather than relying on a single standardized setup.

2. Typical Cross-Industry Application Scenarios

2.1 Power Construction

At substation and power grid construction sites, spider crane models in the 1.2 to 3-ton range are frequently used to handle components such as disconnect switches and transformers within dense equipment layouts. Their compact working envelope allows lifting tasks to be carried out while maintaining the required safety clearances from live equipment, without occupying large areas of the site or disrupting nearby installations.

2.2 Building and Municipal Engineering

In projects with limited access—such as indoor glass installation, curtain wall construction, or roof steel structure lifting—smaller spider crane models can reach the work area through elevators, doorways, or narrow passages due to their compact body width of around 0.65 meters.

For larger municipal projects, including airports, railway stations, and dam construction, higher-capacity models in the 8 to 16-ton range are used to lift heavy components directly on site. In many situations, this reduces the need for extensive ground preparation or complex leveling before lifting work begins.

2.3 Disaster Relief and Emergency Support

In disaster response operations involving difficult terrain, such as swamps, riverbanks, or snow-covered areas, the crawler chassis allows the crane to move and operate steadily where wheeled equipment often encounters limitations. When fitted with attachments like grab buckets, the crane can assist with debris removal and access clearing during rescue and recovery operations.

In municipal emergency repair work, spider cranes are commonly used to lift pipes, manhole covers, and related infrastructure components. Their ability to work within narrow road sections helps shorten repair cycles and reduces the duration of traffic restrictions.

2.4 Industry and Manufacturing

In factory workshops where overhead bridge cranes limit available space, spider crane models in the 2 to 5-ton range are used for equipment maintenance, cable replacement, and material handling. Low operating noise allows these tasks to be carried out without significantly affecting normal production activities.

In automotive manufacturing environments, spider cranes are also used for parts transfer and assembly assistance, particularly in areas where fixed lifting systems are difficult to install or reposition.

3. Use, Maintenance, and Safety Guidelines

3.1 Common Problem Solutions

Obstacle Avoidance in Narrow Spaces: Select a remote-controlled model. Adjust the boom angle in real-time by observing the surroundings, utilizing the compact body to navigate through gaps in equipment.

3.2 Ground Protection Requirements

Prioritize rubber-tracked models to avoid damage to indoor floors and green areas.

3.3 Extreme Environment Operations

In low-temperature environments, select electric-start models. In high-temperature environments, pay attention to hydraulic system cooling and check oil temperature regularly. 4. Maintenance and Care Points: Lubrication and maintenance must strictly adhere to the recommended schedule: Red-marked lubrication points should be injected weekly with molybdenum heavy-duty engine oil using an oil gun; green-marked engine oil should be changed every 100 hours using S110W-30 engine oil; yellow-marked reducer oil should be applied every 100 hours using CKC220 mineral gear oil. The turntable and boom require maintenance every 20 days, and grease must be applied before extending the boom to prevent wear. The equipment must be stored in a dry, well-ventilated environment, protected from rain. If not in use for extended periods, recharge the battery monthly.

3.4 Safety and Compliance Requirements

Before operation, verify the ground’s load-bearing capacity; soft ground requires the use of mats. Operators must be familiar with the equipment’s operating procedures and strictly adhere to the operating radius and load specifications specified in the lifting load chart during hoisting. The equipment must be regularly inspected for wire rope wear, outrigger hydraulic system sealing, and the integrity of welded joints.

4. Industry Trends and Selection Recommendations

When choosing a crawler spider crane, decisions are usually driven by site conditions—such as available space, load weight, and required working radius—rather than by rated capacity alone. Models in the 1.2 to 2-ton range are commonly used for indoor or restricted-access lifting, while 3 to 5-ton units are more typical in power maintenance and smaller municipal projects. For larger construction sites or emergency response work, higher-capacity models from 8 to 16 tons are often selected.

Beyond basic capacity, practical considerations such as power type, available space for outrigger deployment, accessory requirements, and an appropriate safety margin all influence final selection. In parallel, the market is gradually shifting toward more advanced control systems, modular configurations, and wider adoption of dual-power setups. In everyday use, crawler spider cranes are increasingly treated as adaptable lifting tools for varied site conditions, rather than as equipment limited to a narrow range of specialized tasks.

5. Conclusion

In day-to-day work, crawler spider cranes are mainly used in situations where conventional lifting equipment is difficult to deploy. Their compact layout, crawler travel system, and flexible outriggers make it possible to operate in narrow spaces, uneven ground, and other complex site conditions often encountered in power construction, municipal projects, emergency work, and industrial facilities.

In practice, long-term reliability is influenced not only by the machine itself, but also by how it is selected, operated, and maintained on site. Following applicable safety standards, choosing suitable power options, and matching the right attachments all contribute to stable performance over time. Meanwhile, the wider use of remote controls, modular components, and dual-power configurations is gradually making these cranes suitable for a broader range of lifting tasks.

With multiple capacity options and configurable features, crawler spider cranes can be matched to different working spaces, load requirements, and operating radii. Rather than replacing traditional cranes, they serve as a practical complement, helping users handle lifting tasks that require compact access, controlled movement, and adaptable deployment.

Introduction

Knuckle boom cranes, with their unique foldable articulated boom design, are becoming the preferred lifting solution from bustling cities to remote construction sites. They perfectly balance powerful lifting capacity with exceptional space adaptability, and through quick changes of various attachments, they achieve versatility, significantly improving operational efficiency and safety.